Sugar production is a cost-sensitive business. Robust, durable and high-quality process instrumentation is of utmost importance because it increase performance of your sugar factory and ensures constant quality. Sugar manufacturing processes can be optimized without compromising product quality. Easy-to-clean, reliable and innovative measurement technologies guarantee high plant availability and reduce the risk of equipment damage during maintenance.

Key facts

182

million metric tons of sugar

were produced worldwide in the 2020/2021 crop year. 80% of the world's sugar is produced from sugar cane and the remaining 20% comes from sugar beets. A total of over 120 countries produce sugar. Source: www.investopedia.com

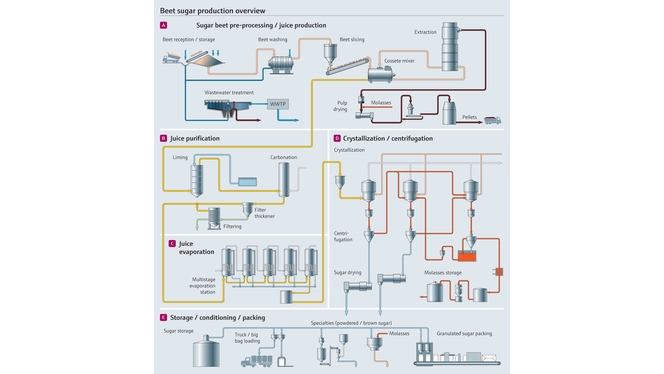

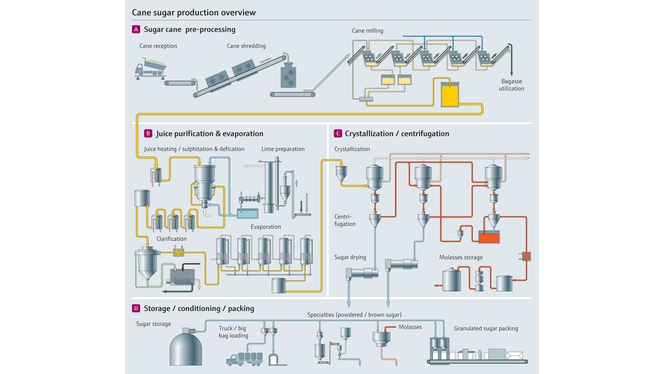

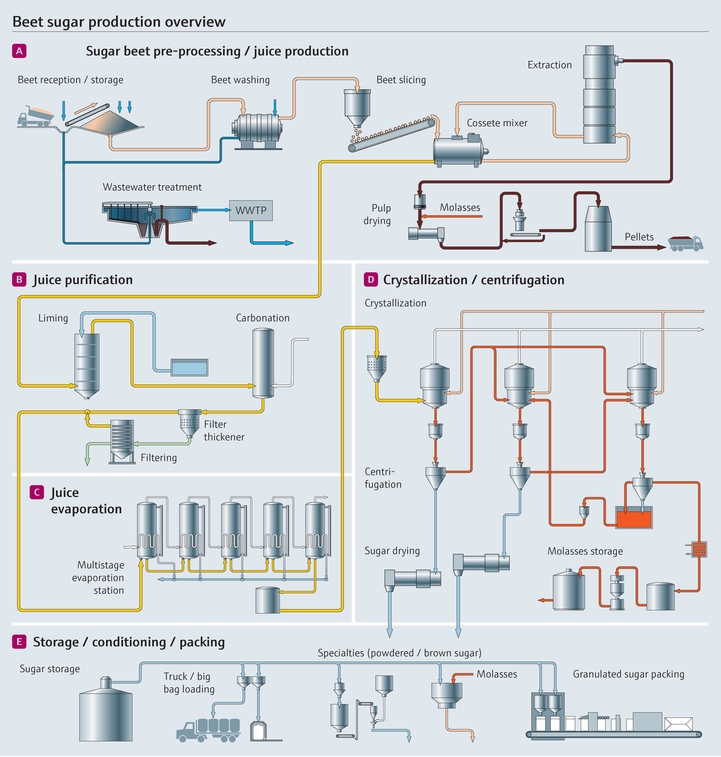

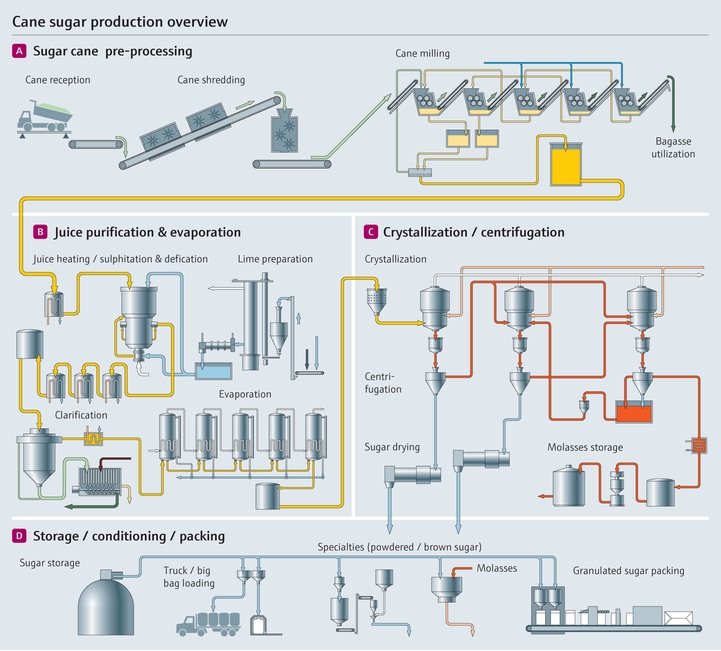

Sugar manufacturing processes

Click through the maps to learn more about how to improve and optimize your sugar production.

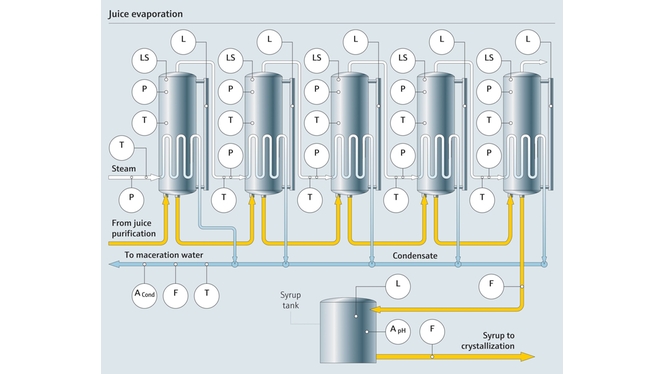

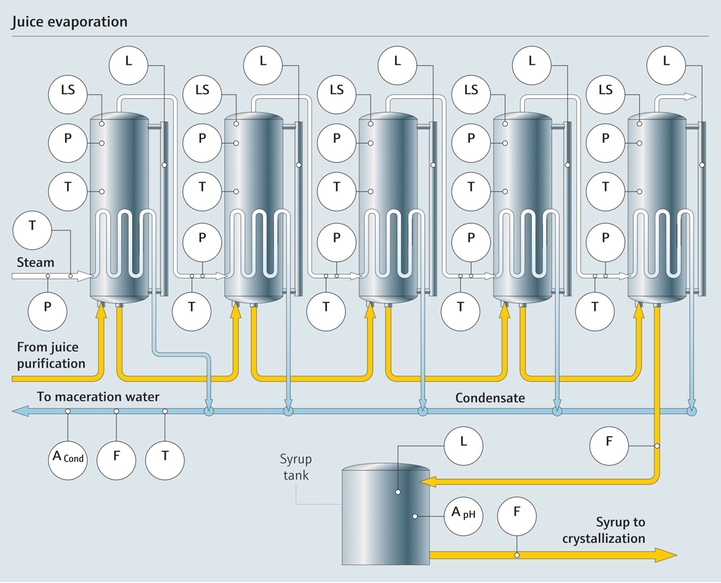

Level measurement in the evaporation process

One of the most challenging applications in sugar production is level measurement in the evaporator. A low clarified juice level may damage an entire batch and cause an unscheduled outage.

Our expertise in the field

Radar technology mounted in a bypass system ensures robust, stable and reliable level monitoring.

- Optimize your level measurement in the evaporation process using radar level measurement, for example with our free space radar Micropilot FMR60.

Optimize your differential pressure measurement

Harsh production environments and cleaning processes frequently damage the differential pressure system in evaporators.

Our expertise in the field

Our innovative electronic differential pressure system is a reliable one-to-one replacement.

- Maximum robustness paired with abrasion resistance and vacuum tightness thanks to the ceramic cell of Deltabar FMD71. In addition, Deltabar offers faster installation, less maintenance and downtime as well as fewer spare part warehousing.

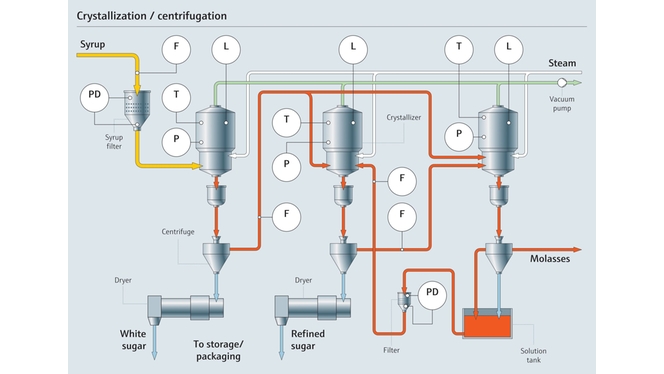

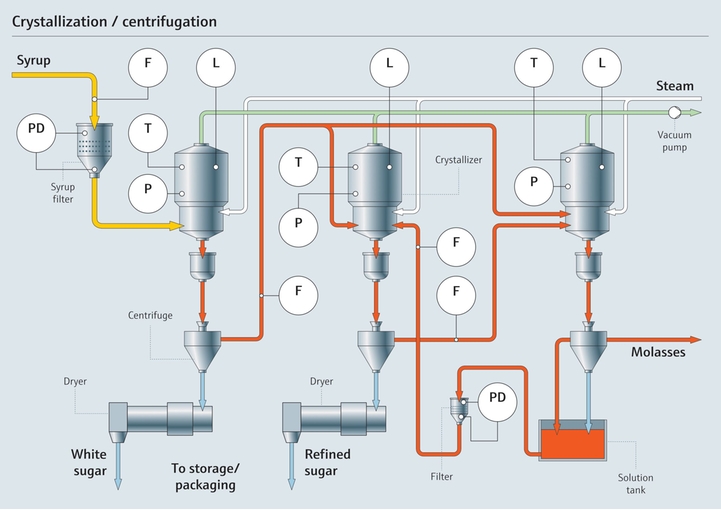

Keep pH measurement within safe limits

The optimal pH range in the sugar crystallization process is pH 6.5 to 7.0, which ensures top-quality end products. Because of the low ionic strength of the water mixed with sugar, a glass electrode cannot be used.

Our expertise in the field

We recommend our digital non-glass sensors with ISFET or enamel electrode combined with Memosens technology.

- Identify the potential of using our digital non-glass pH sensor CPS77E with ISFET electrode.

- Benefit from long-term stability and minimal maintenance using Ceramax CPS341D, the digital non-glass pH sensor with enamel electrode.

- Increase process safety and simplify handling thanks to Memosens sensor technology.

Brix concentration at the highest level

Syrup is produced in the evaporation phase with about 65° Brix. Reliable and accurate results at the right moment are key.

Our expertise in the field

Apart from the main task of measuring mass flow and density, the Promass also performs an in-line measurement of the Brix concentration with a high degree of accuracy. Furthermore, Promass provides clear, standardized diagnostic notifications using the Endress+Hauser Heartbeat Technology, which enables predictive maintenance while supplying proof of operational reliability and process safety.

- Discover the benefits of Endress+Hauser's Coriolis mass flowmeters.

- Analyze the potential of our smart instrumentation with Heartbeat Technology related to predictive maintenance.

Benefits

As a sugar manufacturer, you must minimize downtime or other risks during the sugar production process. For that reason, you need a reliable partner at your side. Our experienced industry and application engineers can help you optimize your processes and improve plant availability.

Key facts

24/7

production without interruptions or outage.

Key facts

NO

faulty or damaged process instrumentation during production and maintenance.

Key facts

More than 1,000

Endress+Hauser process instruments installed in every sugar plant help you to improve plant availability.

Our offering

Endress+Hauser offers a complete palette of approved flow, level, temperature, pressure and analytical instruments to solve your challenges in the demanding sugar production business. Our instruments are designed and manufactured to withstand cleaning processes during maintenance periods and in harsh production processes.

- Consistent product quality

- Stable processing parameters (Brix, etc.)

- Safety for your installed base such as flow meters or other process-relevant equipment

- Reduced outage