在向净零经济过渡的过程中,氢能正成为应用前景广阔的能源载体,帮助石油与天然气行业实现碳减排目标。氢气的运输、储存、使用都面临诸多挑战,准确可靠的专业测量建议至关重要。我们的产品组合性能卓越,运行安全,支持溯源归档记录,确保符合法规和环保要求。

关键点

800亿美元

到2050年,全球氢能基础设施年均投资额预计将增长十倍,达到800亿美元(IEA)

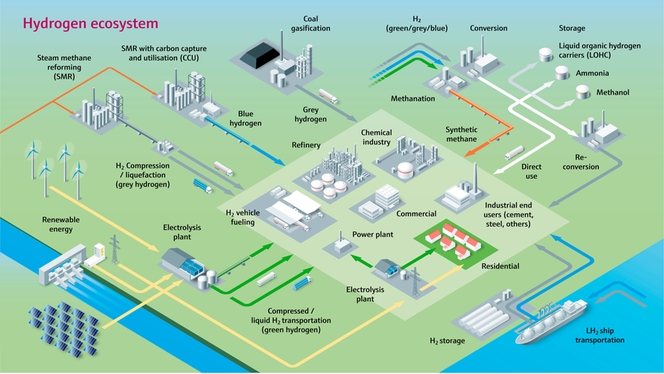

氢生态系统

氢能是实现脱碳目标、可再生能源集成和零碳交通的主要途径。氢气是清洁能源,应用广泛,为向清洁能源过渡转型提供了整体方案。全球需求来自炼油厂、合成氨生产,以及其他行业。化石燃料、生产过程产物、生物质和可再生能源均是可能的制氢原料。氢气按照生产来源分为灰氢、蓝氢和绿氢,可以通过管道、卡车、轮船输送气态或液态氢气(LH2)。

电解槽出口的氢气质量达标

利用太阳能、风能等可再生能源发电,电解制备绿氢,能够储存大量能源,方便人们按需使用。电解是指利用电能将水分解成氢气和氧气的过程。氢气有高质量标准要求,具体取决于不同的运输方式和最终用途,尤其是燃料电池应用(ISO 14687:2019)。

我们掌握专业知识

采用光学分析技术测量水分(H2O)和氧气浓度(O2),仪表坚固耐用,工作可靠,免维护。Endress+Hauser的光学分析仪表具有以下优点:

- 及时识别过程杂质,响应时间非常短

- 无可移动部件,无需充注电解液,光学部件使用寿命长,维护成本非常低

- 内置检测部件性能稳定,仪表坚固耐用,超长正常运行时间

- 采用Heartbeat Technology心跳技术,配备健康状况监测功能,仪表安全调试轻松便捷,可实现长时间免维护运行

天然气掺氢管网

氢气可以通过现有天然气基础设施运输,取决于实际管路状况。向天然气燃料系统或管路注入氢气后,甲烷浓度就会降低,进而减少二氧化碳体积。法规规定,天然气掺氢的允许比例范围在10...20%之间。高精度流量测量和精准组分测定技术对于确保混合物的体积和质量至关重要。

我们掌握专业知识

选用Endress+Hauser的科里奥利质量流量计,轻松执行高精度、高稳定性测量,有效控制进入天然气管道的氢气的流量。利用拉曼光谱技术测定气体组分,能够可靠识别常见天然气组分,从而确定最终掺氢比例。

- 利用拉曼光谱技术安全进行组分测量:拉曼光谱分析仪最多可配置四个测量通道,光纤长达150米,可用于长距离天然气掺氢管路中的氢气浓度监测。

- 在线测量有助于提高操作安全性,缩短响应时间:探头与分析仪分离安装,无需向分析仪传输样气。

- 科里奥利质量流量计胜任气体的多参数测量,包括质量流量、密度、温度和校正体积流量。

测量水质参数,服务绿氢制取

电解过程需要使用超纯水。制取1 kg的氢气需要9 kg的超纯水,相当于近30 kg的海水。水质不达标会干扰电解槽的平稳运行,导致运营成本增加。电导率是关键水质参数。通常,碱性电解槽要求电导率不超过1 μS/cm,而PEM电解槽则要求电导率不超过0.1 μS/cm。

我们掌握专业知识

现今,地球上部分地区淡水资源短缺,海水成为了重要的水资源。因此,需要进行多级水处理,确保水纯度满足电解槽正常运行的要求。需要密切监测反渗透膜进水的水质,以便控制处理效率、触发清洗或再生操作,确保水质达标。Endress+Hauser的传感器和分析仪型号丰富,胜任上述过程监测任务。

- 多通道变送器平台搭载多款Memosens 2.0 数字式水质传感器,操作轻松灵活。

- 在碱性电解槽中,基于pH值控制碱性电解液;Memosens 2.0是先进的数字技术,确保过程可靠,长正常运行时间

- 对于工业制氢装置,精准监测给水中的有机污染物(TOC总有机碳)或硅酸盐、钠离子等杂质的浓度变得越来越重要。

液态有机物储氢(LOHC)—— 储存和运输氢气的便捷方法

液态有机物储氢(LOHC)技术使用有机液体化合物,通过化学反应吸收和释放氢气。LOHC是利用现有基础设施远距离储存和运输氢气的可行方式。

我们掌握专业知识

氢化和脱氢工艺均为高温过程。过程中有多个关键测量点,对于反应过程的监测和控制至关重要。Endress+Hauser助力工厂保证生产效率,过程安全和产品质量。

- 齐全的现场仪表、服务产品和解决方案组合

- 科里奥利质量流量计、热式质量流量计和涡街流量计,配备在线仪表自校验功能,优化加氢工艺

- 高精度储罐液位测量

伺服液位计用于液氢储罐的高精度液位测量

液态氢需要低温储存,-253°C (-423.4°F)的极端低温工况、沸腾体、蒸汽压力给液位测量带来了巨大挑战。为了确保储罐的安全运行,精准测得库存量,可靠工作的液位计和独立工作的溢罐报警装置必不可少。

我们掌握专业知识

Endress+Hauser的伺服液位计直接接触被测介质,进行高精度液位测量。这种测量方法和测量技术不受蒸汽压力和温度的影响,能够安全、可靠、精准测量液态氢的液位和密度。

- 可靠进行高精度液态氢的液位和密度测量,提高了安全性

- 定期校验仪表,无需中断过程

- 确保储罐操作安全精确

蒸汽甲烷重整(SMR)和蓝氢

蒸汽甲烷重整(SMR)是炼油厂制取氢气最常使用的工艺。高温工况,需要使用催化剂,以及需要严格控制过程的可变因素都是此工艺面临的挑战。蓝氢制取过程需要通过蒸汽甲烷重整(SMR)捕集过程中的二氧化碳。

我们掌握专业知识

Endress+Hauser的产品组合能够帮助用户优化提高重整工艺的过程效率,同时减少温室气体排放。拉曼光谱技术优势明显,有助于提高蒸汽甲烷重整(SMR)工艺的过程效率,减少碳排放:

- 同时测量天然气和合成气进气,包含H2,服务蒸汽甲烷重整(SMR)工艺优化

- 在采样口直接测量,无需加热样气输气管路

- 无需使用传统方法所需的载气

- 在高压环境中进行无损分析,无需燃烧气体,被测样气直接返回工艺过程

我们为您提供支持

从氢气制取到氢气用气点的整个氢价值链中,高可靠性的测量仪表起着重要的作用。为了保证交易公平和有效推行问责制,必须安装科里奥利流量计进行高精度氢气输气量测量。为了满足质量标准的要求,氢气的质量测量同样非常重要。Endress+Hauser提供技术先进的现场仪表和解决方案,适合氢气制取和液化装置应用。

- 型号齐全的产品组合:一站式高性能测量仪表采购

- 我们能够提供高测量精度和高可靠性的质量、体积、组分测量仪表,独树一帜

- 支持先进的通信协议,各类测量点通用,方便无缝系统集成

- 轻松安装和调试仪表:Endress+Hauser的Heartbeat Technology心跳技术支持仪表健康状况监测,可实现免维护

- 数据经过验证,通过计量交接认证,安全可靠