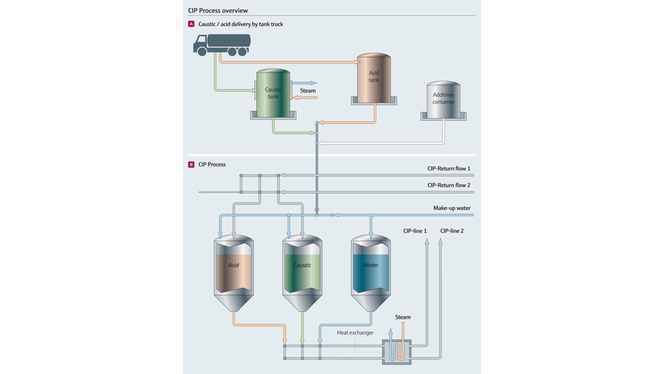

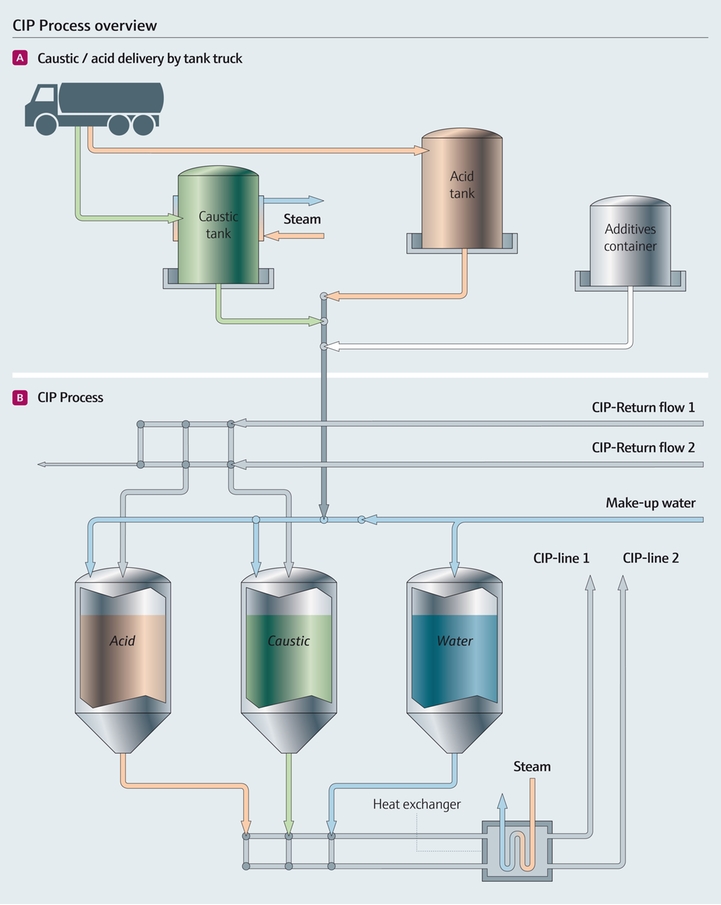

As raw material and energy costs rise, asset utilization within food and beverage plants is becoming even more crucial. Many food processors still operate Clean-In-Place (CIP) systems with little automation, relying on a purely timing-based process and manual verification. Installing inline sensors provides real-time monitoring and control of the cleaning process which helps reduce cleaning time, product loss and resources while ensuring full traceability.

Dữ kiện chính

30%

savings on cleaning agent costs

by ensuring correct detergent strength and phase separation with Endress+Hauser's conductivity and optical measurements.

What you can do

Click through these maps and learn in detail how you can reduce product loss and energy costs in your CIP processes!

Accurate concentration measurement

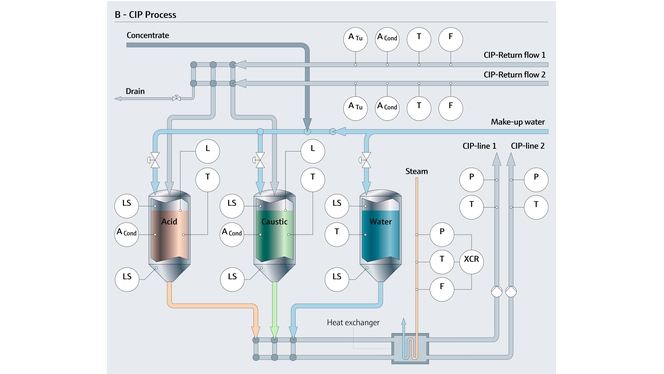

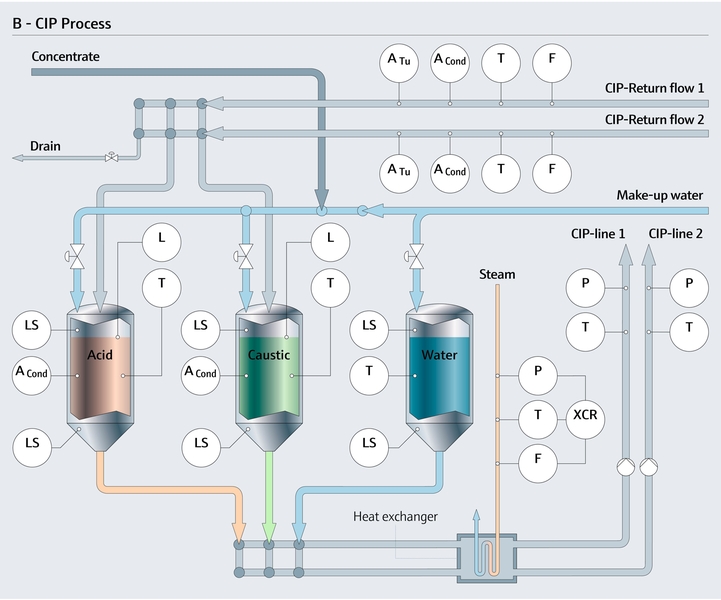

To ensure optimal performance of a CIP system, it is critical to know the detergent concentration both in the loop and the make-up tank.

Our expertise in the field

Conductivity has the lowest maintenance and calibration requirements and enables you to reduce energy, chemical, and water usage. Endress+Hauser offers multiple conductivity sensor and transmitter options specifically designed for CIP applications. From compact entry-level to multi-channel systems with Ethernet integration capabilities.

- Optimize concentration measurement with the right conductivity sensor or transmitter for your application.

Efficient phase separation

Know exactly what is in the line and remove the guesswork. Transition sensors determine when each phase of the CIP cycle ends and the next should begin.

Our expertise in the field

Conductivity, optical turbidity or pH sensors are used to determine when product or rinse water is in the line, starting the CIP system only if zero product remains after rinsing. Fast response is very important to reduce product and water loss and save time.

- Improve your phase separation by choosing the best fit sensor from Endress+Hauser’s liquid analysis portfolio.

Reliable level measurement

Inventory of CIP detergents need to be monitored to ensure stable supply.

Our expertise in the field

Ultrasonic, guided or free-space radar are common methods for inventory monitoring of cleaning agents. Make-up, rinse and recovery tanks are commonly monitored with hydrostatic or capacitive sensors; selection is based on tank size and personal preference. Inventory safety is ensured by low/high level alarms and empty pipe detection (pump protection) and are usually done with tuning fork or conductive/capacitive sensors.

- Identify the best-fit level instrumentation for your application from a broad range of measuring principles and the associated portfolio of products.

Robust flow measurement

Flow measurement is fundamental for an efficient CIP system. By ensuring a strong and turbulent flow, the desired scrubbing effect is reached.

Our expertise in the field

The Proline Promag H line is designed to handle the aggressive chemicals at elevated temperatures and higher than normal vibration due to turbulent flow. Endress+Hauser ensure performance for many years in CIP service. The flowmeters also include a temperature and conductivity output in addition to the flow value.

- Benefit from electromagnetic flowmeters which include a temperature and conductivity output in addition to the flow value.

Cost saving temperature measurement

Temperature within the CIP process can be measured at several locations and is closely controlled to ensure balance of the effectiveness of the cleaning and energy consumption. Often seen as a critical control point, temperature needs frequent calibration.

Our expertise in the field

iTHERM QuickNeck - our patented thermometer extension neck with quick release for fast and easy recalibration. One simple turning movement for opening and easy re-installation after calibration.

- Benefit from fault prevention and time savings using our temperature sensor iTHERM TM411 with QuickNeck technology.

Build-up recognition to ensure cleaning efficiency

Cleaning efficiency is based on temperature, detergent concentration and flow velocity/shear forces at the installation walls. But as the pipes are not always straight and the reach of the spray balls is not always ideal, there are spots which are difficult to clean. To determine and improve the overall cleaning efficiency, it is necessary to also monitor the cleaning behaviour at these spots.

Our expertise in the field

Our compact multiparameter device Liquitrend QMW43 can simultaneously measure the adhesion thickness and conductivity of media. Installed at critical points in the food processing plant, it reliably monitors fluid behavior and informs whether residual buildup is present after cleaning. This innovative technology allows the cleaning frequency and intensity to be tailored to the needs of a plant, thus increasing efficiency.

Benefits

Together with our customers, our employees have achieved remarkable results in the optimization of Clean-in-place processes. Strong industry and application expertise as well as our broad product portfolio ensure first time success. Endress+Hauser’s goal is to be a reliable partner in all aspects.

Dữ kiện chính

25-30%

time saving for each CIP cycle.

Dữ kiện chính

30%

reduced chemical usage by using optical technologies in phase separation.

Dữ kiện chính

>100

countries benefit from our application and industry competence.

Our offering

We understand your challenges in demanding CIP processes and provide you with a full line of hygienic, sanitary measurement solutions. Our proven portfolio of flow, level, pressure, temperature and analytical instrumentation is manufactured to the highest quality standards and meets all food and beverage requirements and regulations. We offer you:

- Robust, reliable and industry-optimized sensors in hygienic design

- Easy to clean and absolutely tight measuring sensors

- Innovative self-diagnostics to ensure full confidence in measurements

- Seamless integration into any control system