Specs at a glance

-

Max. process pressure (static)

500 bar (7252 psi)

-

Maximum standard immersion length

1000 mm (39,37")

-

Max. immersion length on request

5.000 mm (196,85")

Field of application

Due to the challenging process conditions by heavy duty applications the load capacity of a thermowell must be calculated exactly. Dye penetration tests, ultrasound test, helium leakage test, pressure endurance test as well as various, non-destructive material tests prove the quality of materials and processing.

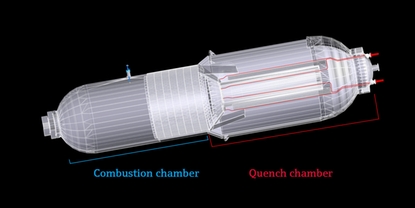

TA576 is designed for use with resistance and thermocouple thermometers mainly in heavy duty applications.

Benefits

The extension, the immersion and the tapering lengths as well as the bar dimensions can be chosen according to process requirements

A wide choice of standard materials and flanged connections is available; special versions can be ordered according to specifications

Different grades of surface finishing are also available

The thermowell stem shape can be straight, conical or conical tapered

The process connection is flanged with double sided standard or full penetration weld

Extended selection

-

High-end products

- Highly functional and convenient

Technical excellence

Simplicity

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

Loading alternative products

Loading alternative products

-

-

Technical Information (TI)

Technical Information

Omnigrad TA series

Industrial protecting tubesEN 26/09/2005Language:

English

Version:

26/09/2005

File size:

127.9 KB

File name:

TI138ten.pdf

-

-

-

Technical Information (TI)

TI TA575, TA576

Industrial thermowell for temperature measurement technology

EN 15/01/202426/05/2014Language:

English

Version:

15/01/2024

File size:

601.2 KB

File name:

TI01128TEN_0224-00.pdf

-

-

-

Technical Information (TI)

Industrial Protecting Tube omnigrad TA576

Heavy duty - General purpose

From round bar stock

Flanged weld type

Also Du Pont SR6T/SR7TEN 01/10/1997Language:

English

Version:

01/10/1997

File size:

103.5 KB

File name:

TI163ten_1097.pdf

-

-

-

Operating Instruction (BA)

Thermowells

Operating instructions for thermowells for EAC approval

EN 01/12/2016Language:

English

Version:

01/12/2016

File size:

1.3 MB

File name:

BA01469TEN_0116.pdf

-

-

-

Special Documentation (SD)

Device viewer

Technical documentation in other languages

Language:

English

Version:

14/07/2021

File size:

478.5 KB

File name:

SD02429R09EN_0121.pdf

-

-

-

Fields of Activities (FA)

Temperaturmesstechnik

Thermometer und Transmitter für die Prozessindustrie

Language:

German

Version:

04/02/2025

File size:

18.9 MB

File name:

FA00006Tde_2325.pdf

-

-

-

Fields of Activities (FA)

Misura della temperatura

Misura della temperatura

Termometri e trasmettitori per l'industria di processoLanguage:

Italian

Version:

09/07/2024

File size:

20.3 MB

File name:

FA00006Tit_2223.pdf

-

-

-

Fields of Activities (FA)

Temperature measurement

Thermometers and transmitters for the process industry

Language:

English

Version:

04/02/2025

File size:

18.8 MB

File name:

FA00006Ten_2325_interaktiv_verb.pdf

-

-

-

Fields of Activities (FA)

Misura della temperatura

Termometri e trasmettitori per l'industria di processo

Language:

Italian

Version:

17/02/2020

File size:

30.6 MB

File name:

FA00006TIT_2020.pdf

-

-

-

Fields of Activities (FA)

Catálogo medición temperatura

Termómetros y transmisores para la industria de proceso

Language:

Spanish

Version:

20/04/2018

File size:

5.5 MB

File name:

FA00006Tes_Catalogo Temperatura_1818.pdf

-