The cosmetics manufacturing process is highly challenging and competition in the worldwide cosmetics market is intense. Change is the only constant in consumer trends, and regional specificities, high raw materials costs and countless regulations add complexity. In the race for market share, time-to-market and manufacturing flexibility are decisive. Our expertise in production automation and smart, reliable instrumentation drives efficient and secure manufacturing to bring a competitive edge.

Key facts

806

billion USD

expected global market value cosmetics products by 2023 Source: Global Cosmetics Products Market Analysis of Growth, Trends and Forecasts (2018-2023), Orbis Research.

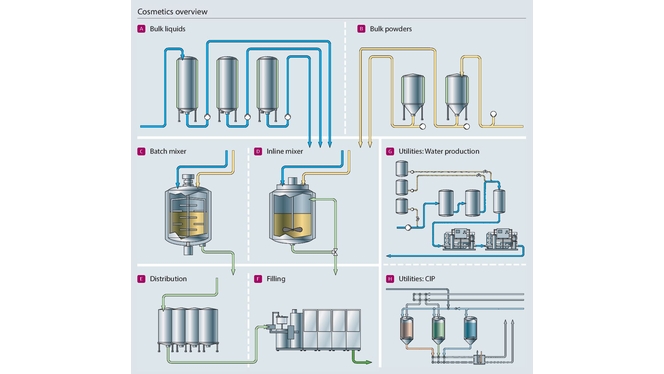

Find out where we support your manufacturing processes

Overview of the processes in the cosmetics production

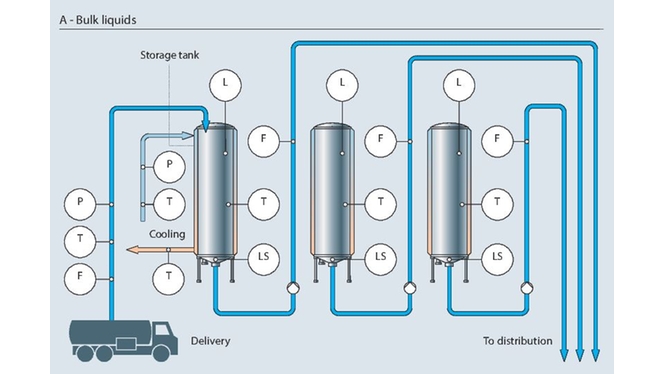

Measuring points in the storage of bulk liquids

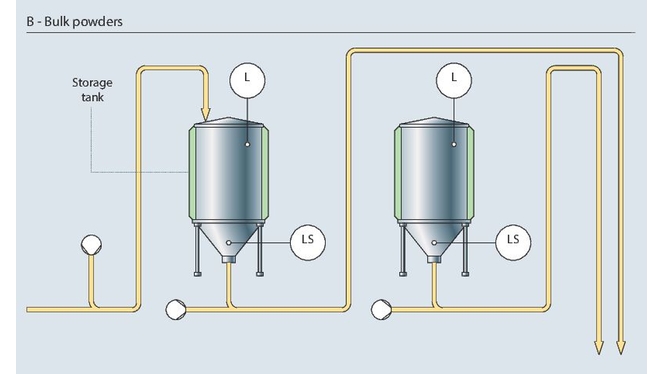

Measuring points in the storage of bulk powders

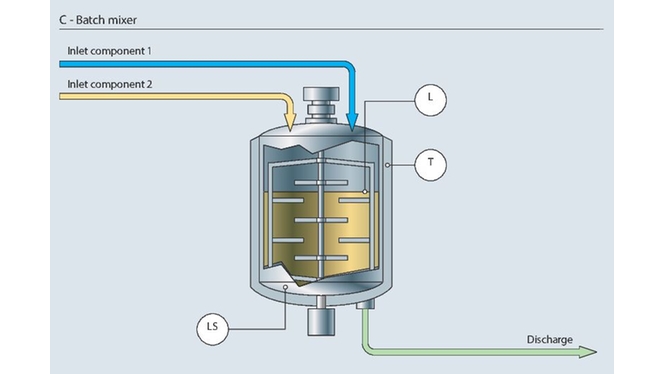

Measuring points in a batch mixer

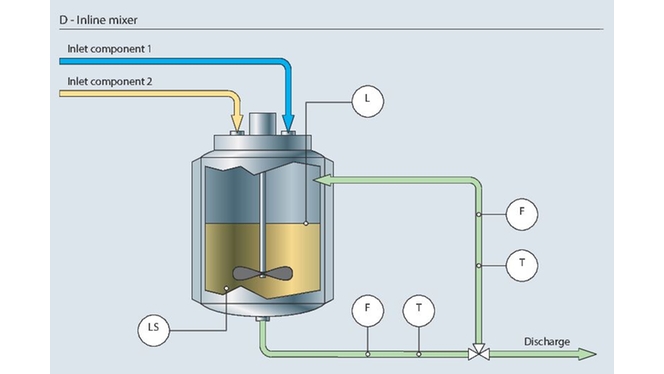

Measuring points in an inline mixer

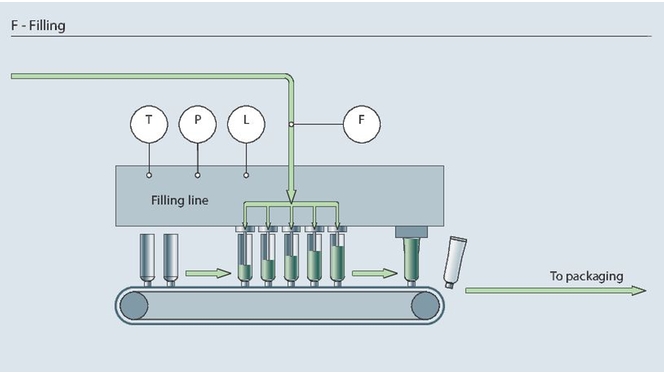

Measuring points in the filling line

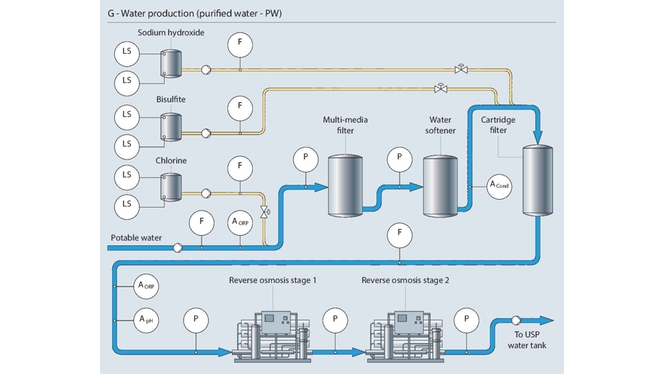

Measuring points in the water purification process

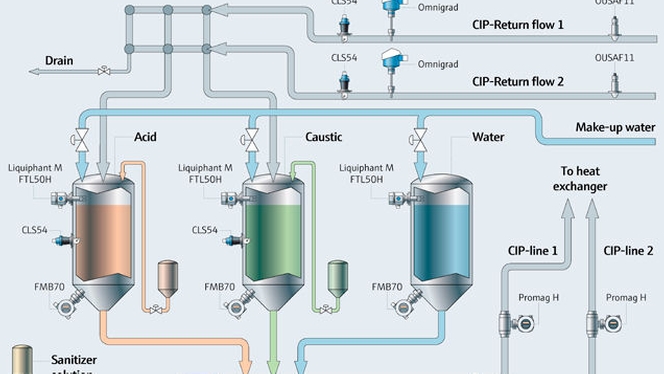

Measuring points in the cleaning in place process

Overview of the processes in the cosmetics production

Measuring points in the storage of bulk liquids

Measuring points in the storage of bulk powders

Measuring points in a batch mixer

Measuring points in an inline mixer

Measuring points in the filling line

Measuring points in the water purification process

Measuring points in the cleaning in place process

Enhanced stock control

Active ingredients in cosmetic manufacturing are high-cost and must be stored and monitored properly to minimize wastage. Multiple technologies are required to measure stock, such as hydrostatic pressure sensors, radar level and capacitance measurement.

Our expertise in the field

Our integrated technologies offer modern and reliable solutions for the management of stock inventory and the reduction of waste, with easy maintenance and real time monitoring.

- Optimize measurement with instrumentation for each application

- Protect storage processes against overfill and leaks with our Liquiphant FTL50H

- Reduce waste and bring down costs with smart instrumentation

Accurate mixing

Mixing is the most demanding step in cosmetics manufacturing and key in determining the quality of the final product. Accurate addition and mixing of raw materials, as well as efficient use of energy and water, is vital to minimize waste and reduce costs. Handling oil-based and sticky products with various viscosities and densities can also pose significant challenges.

Our expertise in the field

Our engineering processes and smart, reliable instrumentation enable accurate and optimal mixing to help ensure the best product quality.

- Rely on Promass I for accurate flow and viscosity measurement

- Use Liquiphant and Liquipoint FTW33 for safe and smooth processes with sticky products

- Minimize energy losses with energy monitoring and management solutions

Precise filling and dosing

Ensuring that the exact amount of product is filled every time accurately and continuously is indispensable in the cosmetics production process. Furthermore, mechanical filling and dosing components can bear high maintenance costs and be unreliable, triggering lengthy process interruptions.

Our expertise in the field

Our Coriolis flowmeters bring high and dependable accuracy to your batch and filling processes.

- Integrate digital communications protocols

- Take tight control of the entire filling process

- Save costs by avoiding mechanical instrument components

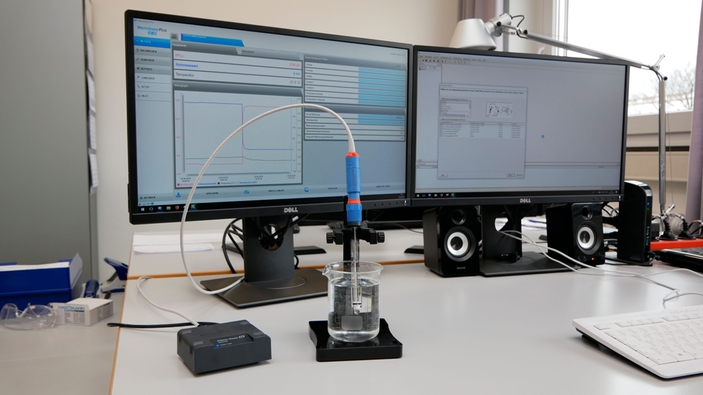

Rapid calibration and maintenance

Calibration and maintenance activities can result in time consuming and costly downtime of production. Shut down periods must be reduced to an absolute minimum if productivity KPIs are to be met.

Our expertise in the field

At Endress+Hauser, calibration is one of our core competences. We offer a full portfolio of on-site calibration services for optimized operations, full compliance and minimized downtime.

- Minimize calibration times with Endress+Hauser on-site mobile flow rigs

- Rely on fully traceable and accredited calibration facilities

- Ensure ongoing production compliance with regular and professional calibration

Total compliance

To identify issues that can affect the quality of your cosmetic products, compliance to standards such as ISO 17025 and the FDA Cosmetics GMP is crucial. Guidance states that equipment should be calibrated regularly or checked according to an SOP with results documented where appropriate.

Our expertise in the field

Our products, services and solutions come with all the right certification and documentation for GMP regulated facilities.

- Comply to all necessary standards for good manufacturing practice (GMP)

- Trust calibration professionals from Endress+Hauser

- Have all necessary documentation at hand

Benefits

The world of cosmetic products is fast-moving. Endress+Hauser has over 65 years of experience in improving our customers’ processes with our process knowledge and industry expertise. We understand your challenges and are committed to finding the best solution to your application needs, so you can keep cost under control and achieve the fastest time-to-market possible.

Key facts

100%

of the parameters of your process covered

Key facts

100%

of production compliant to quality standards

Key facts

10%

reduction in energy costs within 18 months in industrial facilities achieving ISO 50001 certification

How we can help

With our complete portfolio of instrumentation for all cosmetics manufacturing processes, Endress+Hauser can help you meet consumer expectations and safety standards whilst mitigating risk and hitting efficiency and sustainability goals.

- On-site calibration for full compliance and improved availability

- Innovative instrumentation for minimal energy consumption and raw materials losses

- Inline quality parameters measurement for optimal viscosity and density control

- Flowmeters for accurate and continuous dosing and filling