The oil & gas industry operates in tough environments with challenging KPIs and costly maintenance when things go wrong. Plant managers and engineers face increasing complexity in their systems and constant pressure to reduce operating costs, improve reliability (uptime) and increase process efficiency. You need better visibility of the condition of your process equipment to avoid costly unscheduled maintenance and reduce downtime.

Key facts

$150 billion

Potential industry value of digital predictive maintenance initiatives and technologies 2016-25 (Source: Digital Transformation Initiative: Oil and Gas Industry White Paper, World Economic Forum, January 2017, p.13)

How advanced instruments & digital services can support you

A range of our smart instruments for the oil and gas industry are equipped with Heartbeat Technology that provides high system availability with minimal effort and is a key enabler of IIoT solutions.

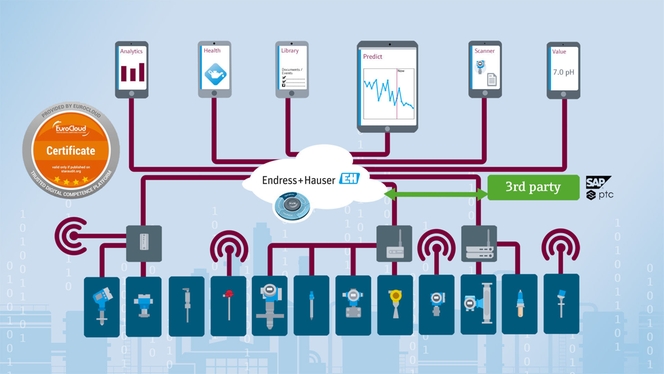

Our Netilion IIoT ecosystem provides actionable information at the right time about your field devices to vastly improve maintenance efficiency. It is open to 3rd-party field devices and clouds.

The Netilion ecosystem and portfolio of apps unlock the full potential of your field instrumentation to give you the insight you need to reduce downtime and maintenance costs.

A range of our smart instruments for the oil and gas industry are equipped with Heartbeat Technology that provides high system availability with minimal effort and is a key enabler of IIoT solutions.

Our Netilion IIoT ecosystem provides actionable information at the right time about your field devices to vastly improve maintenance efficiency. It is open to 3rd-party field devices and clouds.

The Netilion ecosystem and portfolio of apps unlock the full potential of your field instrumentation to give you the insight you need to reduce downtime and maintenance costs.

Permanent device and process diagnostics

To avoid costly unscheduled maintenance and downtime you need to ensure that your instrumentation and key process parameters are constantly performing to specification. And in the event of an issue with a device you want immediate and clear guidance on what to do.

Our expertise in the field

The diagnostic capability of Heartbeat Technology allows our field devices to continuously self-monitor themselves providing a health check of your instrumentation and processes to ensure key parameters are performing within specification. With continuous diagnostic checks of everything from the sensor to the output signal, you can be sure your measurements are reliable.

- Ensure high device reliability and safe plant operation

- Clear error messages and corrective guidance enable cost-effective, simplified condition-based maintenance

- Leverage in-depth diagnostic coverage of up to 98%

Instrument verification without interrupting the process

Periodic verification to assess the functional performance of an instrument is often required to fulfil external or internal compliance requirements, e.g. regulatory, legal, contractual, quality or safety-related. You need to verify that your devices are functioning correctly with minimal process interruption, ideally without removing the instrument from the process.

Our expertise in the field

Heartbeat Technology allows you to verify that your devices are functioning correctly directly at the measuring point, without process interruption. A simple guided procedure generates a test report with clear results along with a verification protocol required by regulators, laws and standards.

- Reduce effort by verifying anytime anywhere, saving time in the field

- Reduce proof-testing costs and extend your test cycles

- Devices with Heartbeat Technology include SIL wizards for guided proof tests

Real time data for trend analysis and predictive maintenance

Devices in constant use can develop issues because of process influences that can reduce measurement performance and lead to costly unplanned downtime. But it can be hard to know the exact condition of your instruments and processes and what maintenance or process actions are needed, and when.

Our expertise in the field

The monitoring function of Heartbeat provides detailed instrument and process data to facilitate condition-based maintenance. Examples include detecting the extent of coating build-up on radar-based level devices and in flowmeter tubes, permitting optimization of their cleaning cycles. Reliable detection of corrosion and abrasion in flowmeters are other examples. This visibility into the condition of your devices and processes permits trend analysis, making predictive maintenance possible.

- Know when equipment and assets will need service or are likely to fail

- Plan targeted service according to actual need / preventive maintenance to minimize costly unplanned downtime

- Recognize trends from instrument and process data to enable predictive maintenance

Greater insight and value with our digital services

Your field devices collect a huge amount of data, and most of it is unused. To take maintenance management to the next level this wealth of data needs to be analyzed and translated into actionable knowledge.

Our expertise in the field

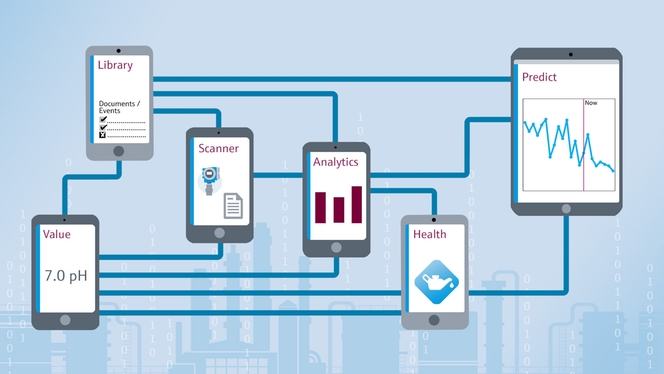

For this we developed Netilion, our IIoT ecosystem. Built upon our more than 15 years’ experience of Life Cycle Management concepts like W@M, this platform and growing portfolio of intelligent apps unlocks the full potential of your field instrumentation to give you more information and insight to vastly improve maintenance efficiency.

- Harness the power of connected data and analysis to deliver the outcomes you care about

- 3rd party devices can also connect and benefit

- Extensive Heartbeat data enables the richest IIoT insights and benefits

Netilion Health: have it under control everywhere

When an unexpected event occurs on a key component of your plant, it is crucial to act quickly. The traditional control and asset health management systems might inform you in real-time about the status of the assets. But it is often necessary to be there on the spot and when something is reported, clear instructions on how to solve the problem can be missing.

Our expertise in the field

The Netilion Heath service and app ensures you have the essential know-how right at hand so you can take quick action. Health identifies the error, accesses precise information from the device manufacturer, and gives clear instructions on how to solve the issue. And there’s no need to rush back to the office to search for the correct documentation – as the Health app delivers it to your smartphone or tablet.

- Asset maintenance made easy - always have the right information at hand

- Track the health history of key devices for deeper insights

Netilion Predict

Minimizing unscheduled and unnecessary downtime and identifying the optimum timeframe for carrying out maintenance on a device are vital challenges. You need the right information at the right time and true visibility into the condition of your equipment.

Our expertise in the field

Coming soon. Our predictive maintenance app makes concrete predictions based on the condition of your devices. Built upon the continuous recording and analysis of monitoring data, the app calculates the optimum timeframe for carrying out maintenance on a device, minimizing unscheduled downtime, reducing maintenance costs, and increasing system availability. The service will also support 3rd party instrumentation.

Benefits

Integrated in a wide range of our instruments Heartbeat Technology provides status, diagnostic and monitoring data that allows you to service and maintain your systems exactly when needed. When paired with our digital services, previously untapped data from your field instruments and processes can be analyzed to provide the insight you need for preventive and predictive maintenance to vastly improve maintenance efficiency and optimize your processes.

Key facts

>65

years of process technology experience along with decades of R&D in digital technologies

Key facts

>90%

of Endress+Hauser’s product portfolio is capable of digital communications

Key facts

>15

years of W@M Life Cycle Management experience

How we can help

To increase plant availability our intelligent instrumentation provides diagnostics, verifies performance, and monitors instrument and process data. Pairing the device data with our growing IIoT ecosystem will further boost maintenance efficiency, enabling the deployment of preventive and predictive maintenance strategies, and the optimization of your processes over the entire life cycle.

- Continuous process and device diagnostics that make sense for you, and verification without process interruption

- Monitoring enables proactive maintenance planning and trend analysis making condition-based and predictive maintenance possible

- The Netilion IIoT ecosystem unlocks the full potential of field instrumentation, vastly improving maintenance efficiency and automatically distributing useful information to those who need it around the clock

- Heartbeat Technology enables the richest IIoT insights and benefits