©Endress+Hauser

Proline t-mass 65F with flanges for industrial gases and compressed air

Sản phẩm mới

Inline flowmeter with long-term stability and a compact, easily accessible transmitter

Thông tin bổ sung

Inline flowmeter with long-term stability as remote version with up to 4 I/Os

Thông tin bổ sung

Sản phẩm đơn giản

Dễ lựa chọn, cài đặt và vận hành

Công nghệ vượt trội

Đơn giản

Sản phẩm tiêu chuẩn

Đáng tin cậy, mạnh mẽ và ít bảo trì

Công nghệ vượt trội

Đơn giản

Sản phẩm cao cấp

Chức năng cao và tiện lợi

Công nghệ vượt trội

Đơn giản

Sản phẩm chuyên dụng

Dành cho các ứng dụng đòi hỏi cao

Công nghệ vượt trội

Đơn giản

Lựa chọn FLEX

Công nghệ vượt trội

Đơn giản

Lựa chọn Fundamental

Đáp ứng nhu cầu đo lường cơ bản

Công nghệ vượt trội

Đơn giản

Lựa chọn Lean

Xử lý dễ dàng các quy trình cốt lõi

Công nghệ vượt trội

Đơn giản

Lựa chọn Extended

Tối ưu hóa quy trình bằng công nghệ tiên tiến

Công nghệ vượt trội

Đơn giản

Lựa chọn Xpert

Làm chủ các ứng dụng khó khăn nhất

Công nghệ vượt trội

Đơn giản

Product headline

std_productprofile_product_usp_12695.

Sensor features

std_productprofile_product_benefits_12697. Cost-effective measurement – easy installation, negligible pressure loss and maintenance-free.

Transmitter features

Reliable flow trending – multivariable measurement. std_productprofile_product_benefits_12703. std_productprofile_product_benefits_12704.

Nominal diameter range

DN 15 to 100 (1/2" to 4")

Wetted materials

Transducer: 1.4404 (316L); Alloy C22, 2.4602 (UNS N06022)

Measured variables

Mass flow, temperature, volume flow, energy flow

Max. measurement error

Gas: 1.5% o.r. (10 to 100% o.f.s.), 0.15% o.f.s. (1 to 10% o.f.s.)

Measuring range

0.5 to 3750 kg/h (1.1 to 8250 lb/h)

Medium temperature range

-40 °C to +100 °C (-40 °F to +212 °F)

Ambient temperature range

-20 °C to +60 °C (-4 °F to +140 °F)

Transmitter housing material

Transmitter housing:

Display/Operation

Liquid crystal: back-lit, two lines with 16 characters per line

Outputs

4-20mA HART (active/passive selectable), pulse, frequency, status

Digital communication

HART, PROFIBUS DP, PROFIBUS PA, FOUNDATION Fieldbus, Modbus RS485

Power supply

85 to 260 VAC, 45 to 65 Hz

Pressure approvals and certificates

Hygienic approvals and certificates

Oxygen service (certified acc. To BS IEC 60877)

Tải xuống nhiều nhất

Proline t-mass 65F, 65I

Thermal Mass Flow Measuring System

Direct Mass Flow

Measurementof Gases

EN

VI

BG DE FR HU IT JA PL RU ZH

01/12/2014

01/07/2010

01/12/2006

01/12/2005

Ngôn ngữ:

Tiếng Anh

Phiên bản:

01/12/2014

Cỡ tập tin:

4.8 MB

Tên tập tin:

TI00069DEN_1314.pdf

102 tài liệu

Thermal Mass Flow Measuring System

EN

VI

Tiếng Bungary Tiếng Đức French Tiếng Hungary Tiếng Ý Tiếng Nhật Người Ba Lan Tiếng Nga Tiếng Trung Quốc

01/12/2014

01/07/2010

01/12/2006

01/12/2005

Ngôn ngữ:

Tiếng Anh

Phiên bản:

01/12/2014

Cỡ tập tin:

4.8 MB

Tên tập tin:

TI00069DEN_1314.pdf

Proline t-mass 65

PROFIBUS DP/PA

Operating Instructions

Thermal mass flowmeter

EN

VI

Tiếng Đức Tiếng Ý

01/12/2014

15/10/2010

01/02/2006

Ngôn ngữ:

Tiếng Anh

Phiên bản:

01/12/2014

Cỡ tập tin:

2.5 MB

Tên tập tin:

BA00113DEN_1414.pdf

Proline t-mass 65

MODBUS RS485

Description of the Device Functions

Description of the device functions (options and settings) of the

EN

VI

Tiếng Đức Người Ba Lan Tiếng Nga

01/12/2014

15/10/2010

01/02/2006

Ngôn ngữ:

Tiếng Anh

Phiên bản:

01/12/2014

Cỡ tập tin:

650.4 KB

Tên tập tin:

BA00116DEN_1414.pdf

Proline t-mass 65

PROFIBUS DP/PA

Description of the Device Functions

Description of the device functions (options and settings) of the

EN

VI

Tiếng Đức

01/12/2014

15/10/2010

01/02/2006

Ngôn ngữ:

Tiếng Anh

Phiên bản:

01/12/2014

Cỡ tập tin:

603.5 KB

Tên tập tin:

BA00114DEN_1414.pdf

Proline t-mass 65

FOUNDATION Fieldbus

Description of the Device Functions

Description of the device functions (options and settings) of the

EN

VI

Tiếng Đức

01/12/2014

31/12/2010

Ngôn ngữ:

Tiếng Anh

Phiên bản:

01/12/2014

Cỡ tập tin:

948.4 KB

Tên tập tin:

BA00135DEN_1414.pdf

Thermal Mass Flow Measuring System

EN

VI

Tiếng Séc Tiếng Đức Tiếng Tây Ban Nha French Tiếng Ý Tiếng Nhật Người Ba Lan Tiếng Nga

01/12/2014

01/07/2010

01/12/2005

Ngôn ngữ:

Tiếng Anh

Phiên bản:

01/12/2014

Cỡ tập tin:

2.4 MB

Tên tập tin:

BA00112DEN_1314.pdf

Proline t-mass 65

MODBUS RS485

Operating Instructions

Thermal mass flowmeter for measuring the mass flow of

EN

VI

Tiếng Đức Người Ba Lan

01/12/2014

15/10/2010

01/02/2006

Ngôn ngữ:

Tiếng Anh

Phiên bản:

01/12/2014

Cỡ tập tin:

2.2 MB

Tên tập tin:

BA00115DEN_1414.pdf

Proline t-mass 65

FOUNDATION Fieldbus

Operating Instructions

Thermal mass flowmeter for measuring the mass flow of

EN

VI

Tiếng Đức

01/12/2014

31/12/2010

Ngôn ngữ:

Tiếng Anh

Phiên bản:

01/12/2014

Cỡ tập tin:

1.8 MB

Tên tập tin:

BA00134DEN_1414.pdf

Thermal Mass Flow Measuring System

EN

VI

Tiếng Bungary Tiếng Séc Tiếng Đức Tiếng Tây Ban Nha French Tiếng Hungary Tiếng Ý Tiếng Nhật Người Ba Lan Tiếng Nga Tiếng Trung Quốc

01/12/2014

01/07/2010

01/12/2005

Ngôn ngữ:

Tiếng Anh

Phiên bản:

01/12/2014

Cỡ tập tin:

8.3 MB

Tên tập tin:

BA00111DEN_1314.pdf

Proline t-mass 65

Brief Operating Instructions

Thermal mass flowmeter

EN

VI

Tiếng Đan Mạch Tiếng Đức Tiếng Tây Ban Nha Tiếng Phần Lan French Tiếng Croatia Tiếng Ý Tiếng Bồ Đào Nha Tiếng Nga Tiếng Thổ Nhĩ Kỳ Tiếng Trung Quốc

01/12/2014

01/07/2010

01/04/2007

Ngôn ngữ:

Tiếng Anh

Phiên bản:

01/12/2014

Cỡ tập tin:

2.4 MB

Tên tập tin:

KA00021DEN_1314.pdf

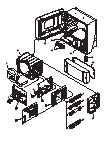

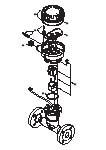

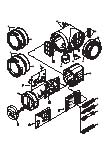

Tìm kiếm phụ tùng theo số trong bản vẽ

60 spare parts & accessories

60 spare parts & accessories

60 spare parts & accessories

Kit power s.b. 40/8X/65 220V REx000

Số bản vẽ

Mã đơn hàng

F

50098557

Kit power s.b. 40/8X/65 220V REx120 Ex

Số bản vẽ

Mã đơn hàng

F

50098558

Kit P.s.b. 40/8X/65 24V REx000

Số bản vẽ

Mã đơn hàng

F

50098565

Kit P.s.b. 40/8X/65 24V REx120 Ex

Số bản vẽ

Mã đơn hàng

F

50098566

Kit 10 fuses 250 VAC T800 MA

Số bản vẽ

Mã đơn hàng

7

50094002

Kit 10 fuses 250 VAC T 2A00

Số bản vẽ

Mã đơn hàng

7

50094003

Kit meas.amplifier t-mass 65 compact Ex

Số bản vẽ

Mã đơn hàng

B

71008429

Kit meas.amplifier t-mass 65 remote Ex

Số bản vẽ

Mã đơn hàng

B

71008430

Kit preamplifier 65 remote sensor Ex

Số bản vẽ

Mã đơn hàng

A

71008448

Kit commodul current/frequency out Ex

Số bản vẽ

Mã đơn hàng

C

50096757

Kit commodul current/freq./2Relay Ex

Số bản vẽ

Mã đơn hàng

C

50098300

Kit commodul Iout passive/Frequency Exi

Số bản vẽ

Mã đơn hàng

C

50098302

Kit commodul Iout active/Frequency Exi

Số bản vẽ

Mã đơn hàng

C

50098303

Kit com 83/65 2x Iout aktiv Exi

Số bản vẽ

Mã đơn hàng

C

50104625

Kit com 83/65 2x Iout passiv Exi

Số bản vẽ

Mã đơn hàng

C

50104626

Kit I/O 50/53/55/83/65/8ME Profib. DP Ex

Số bản vẽ

Mã đơn hàng

C

71021742

Kit I/O Foundation Fieldbus C14 EX

Số bản vẽ

Mã đơn hàng

C

71095035

Số bản vẽ

Mã đơn hàng

C

71066579

Kit Com ModbusRS485+stat.In 2Interf.Ex

Số bản vẽ

Mã đơn hàng

D

71021743

Kit Commodul current out 3 Interface Ex

Số bản vẽ

Mã đơn hàng

D

50096833

Số bản vẽ

Mã đơn hàng

2

50096834

Kit Sub PCB frequency out

Số bản vẽ

Mã đơn hàng

3

50096835

Số bản vẽ

Mã đơn hàng

4

50096837

Số bản vẽ

Mã đơn hàng

6

50098562

Kit disp.50/51/80/90/65 Wall >=V1.06.00

Số bản vẽ

Mã đơn hàng

J

50108131

Kit display mod 50/51/80/65 >=V1.06.00

Số bản vẽ

Mã đơn hàng

E

50108132

Kit connec. board In/Output Wall encl

Số bản vẽ

Mã đơn hàng

23

50094014

Kit connec. board 65 wall encl. non Ex

Số bản vẽ

Mã đơn hàng

24

71008431

Kit Terminal protective Cover Ex

Số bản vẽ

Mã đơn hàng

20

71008445

Kit Bus/connec.b.5X/40/8X/65 field hous.

Số bản vẽ

Mã đơn hàng

G

50094016

Kit Bus PCB/PCB carr.5X/8X/9X/65 wall

Số bản vẽ

Mã đơn hàng

21

50094017

Kit T-DAT Transmitter Data Chip

Số bản vẽ

Mã đơn hàng

1

50094004

Kit S-Dat t-mass 65 programmed

Số bản vẽ

Mã đơn hàng

S

71084176

Kit Termin.Block field hous. 5X/8X/40/65

Số bản vẽ

Mã đơn hàng

29

50108139

Kit Termin.Block Wall encl. 5X/8X/9X/65

Số bản vẽ

Mã đơn hàng

30

50108140

Kit Cover 5X/40/8X/65 version blind

Số bản vẽ

Mã đơn hàng

9

50094028

Kit Cover 5X/40/8X/93/65 vers. blind Exd

Số bản vẽ

Mã đơn hàng

17

50094029

Kit Cover 5X/40/8X/65 with window

Số bản vẽ

Mã đơn hàng

8

50094026

Kit Cover 5X/40/8X/93/65 with window Exd

Số bản vẽ

Mã đơn hàng

16

50094027

Kit Cover Connection terminal

Số bản vẽ

Mã đơn hàng

10

50094038

Kit Cover Connection terminal

Số bản vẽ

Mã đơn hàng

31

50094038

Kit Cover Connection terminal

Số bản vẽ

Mã đơn hàng

31

50094038

Repair kit cover, remote version

Số bản vẽ

Mã đơn hàng

31

71247838

Kit Cover Connection terminal

Số bản vẽ

Mã đơn hàng

10

50094038

Kit Cover 5X/40/8X/93/65 Conn.termi.Exe

Số bản vẽ

Mã đơn hàng

18

50094039

Kit Cover 5X/40/8X/93/65 Conn.termi.Exd

Số bản vẽ

Mã đơn hàng

19

50094040

Kit Seal cover to Wall enclosure

Số bản vẽ

Mã đơn hàng

22

50094041

Kit 10 Seal cover to field housing

Số bản vẽ

Mã đơn hàng

11

50094050

Kit 10 cable glands M20x1,5

Số bản vẽ

Mã đơn hàng

15

50096840

Kit 10 cable glands M20x1.5 Ex

Số bản vẽ

Mã đơn hàng

15

50098036

Kit 10 cable glands M20x1.5 Ex

Số bản vẽ

Mã đơn hàng

15

50098036

Kit 10 cable glands M20x1.5 Ex

Số bản vẽ

Mã đơn hàng

15

50098036

Kit 10 ext. M20x1.5/G 1/2" (plug PVC)

Số bản vẽ

Mã đơn hàng

15

50098041

Kit 10 ext. M20x1.5/G 1/2" (plug PVC)

Số bản vẽ

Mã đơn hàng

15

50098041

Kit 10 ext. M20x1.5/G 1/2" (plug PVC)

Số bản vẽ

Mã đơn hàng

15

50098041

Kit 10 ext. M20x1.5/NPT 1/2" (plug PVC)

Số bản vẽ

Mã đơn hàng

15

50098042

Kit 10 ext. M20x1.5/NPT 1/2" (plug PVC)

Số bản vẽ

Mã đơn hàng

15

50098042

Kit 10 ext. M20x1.5/NPT 1/2" (plug PVC)

Số bản vẽ

Mã đơn hàng

15

50098042

Kit Circuit board cpl field/SS-housing

Số bản vẽ

Mã đơn hàng

12

50096839

Kit Bushing to field/SS-housing

Số bản vẽ

Mã đơn hàng

14

50099102

Kit 2 Screening sheet field housing

Kit Ground terminal / Cover clamp

Số bản vẽ

Mã đơn hàng

13

50096841

Kit housing gaskets 65I/F remote Ex

Số bản vẽ

Mã đơn hàng

29

71009191

Kit Part 65I/F fieldhous.compact non Ex

Số bản vẽ

Mã đơn hàng

25

71009193

Kit Part 65I/F field housing remote Ex

Số bản vẽ

Mã đơn hàng

32

71009192

Transmitter 65, mounting set

t-mass 65, Cable remote version

Chúng tôi tôn trọng quyền riêng tư của bạn

Chúng tôi sử dụng cookie để nâng cao trải nghiệm duyệt web của bạn, thu thập số liệu thống kê để tối ưu hóa chức năng của trang web và cung cấp nội dung hoặc quảng cáo phù hợp.

Bằng cách chọn "Chấp nhận tất cả", bạn đồng ý với việc sử dụng cookie của chúng tôi. Chính sách cookie của chúng tôi.

Tùy chỉnh

Chấp nhận chỉ cần thiết

Chấp nhận tất cả

Chào mừng đến với Endress+Hauser!

Vui lòng chọn thị trường / khu vực của bạn

Thị trường / khu vực

Bangladesh Brunei Cambodia Laos Myanmar Nepal New Zealand Philippines Sri Lanka Taiwan Vietnam

Ngôn ngữ

English

English

English

English

English

English

English

English

English

Chinese English

English Vietnamese

%20with%20flange%20connection%20-%20PP01.jpg)

%20Inline%20version%20with%20flange%20connection%20(remote%20version)%20-%20PP01.jpg)