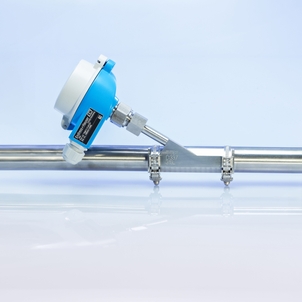

Temperature measurement

Thermometers and transmitters for the process industry

F

L

E

X

Sản phẩm đơn giản

Dễ lựa chọn, cài đặt và vận hành

Công nghệ vượt trội

Đơn giản

Sản phẩm tiêu chuẩn

Đáng tin cậy, mạnh mẽ và ít bảo trì

Công nghệ vượt trội

Đơn giản

Sản phẩm cao cấp

Chức năng cao và tiện lợi

Công nghệ vượt trội

Đơn giản

Sản phẩm chuyên dụng

Dành cho các ứng dụng đòi hỏi cao

Công nghệ vượt trội

Đơn giản

Lựa chọn FLEX

Công nghệ vượt trội

Đơn giản

Lựa chọn Fundamental

Đáp ứng nhu cầu đo lường cơ bản

Công nghệ vượt trội

Đơn giản

Lựa chọn Lean

Xử lý dễ dàng các quy trình cốt lõi

Công nghệ vượt trội

Đơn giản

Lựa chọn Extended

Tối ưu hóa quy trình bằng công nghệ tiên tiến

Công nghệ vượt trội

Đơn giản

Lựa chọn Xpert

Làm chủ các ứng dụng khó khăn nhất

Công nghệ vượt trội

Đơn giản

So sánh

Accuracy

Class AA acc. to IEC 60751

Response time

fastest response time with thermowell t90 starting at below 10 s

Max. process pressure (static)

depending on the configuration up to 100 bar

Operating temperature range

PT100 TF iTHERM StrongSens:

Max. immersion length on request

up to 4.500,0 mm (177'')

iTEMP TMT82 temperature transmitter

HART® temperature transmitter as head, field or DIN rail device with two universal sensor inputs suitable for use in hazardous areas and SIL 2

Accuracy

(Pt100, -50...200 °C) <= 0,1 K

Accuracy

class 2 acc. to IEC 60584

Max. process pressure (static)

at 20 °C: 1 bar (15 psi)

Operating temperature range

Type K:

Max. immersion length on request

up to 4.525,00 mm (178,15'')

Accuracy

Class AA acc. to IEC 60751

Response time

t90 starting at < 1,5 s iTHERM QuickSens

Max. process pressure (static)

depending on the configuration

Operating temperature range

PT100 TF iTHERM StrongSens:

Max. immersion length on request

up to 4.500,0 mm (177'')

Accuracy

Class AA acc. to IEC 60751

Response time

t90 starting at < 1,5 s iTHERM QuickSens

Max. process pressure (static)

depending on the configuration

Operating temperature range

PT100 TF iTHERM StrongSens:

Max. immersion length on request

up to 180"

Accuracy

Class AA acc. to IEC 60751

Response time

depending on configuration

Max. process pressure (static)

depending on the configuration up to 500 bar

Operating temperature range

PT100 TF iTHERM StrongSens:

Max. immersion length on request

up to 1.500,0 mm (59,06'')

Accuracy

Class AA acc. to IEC 60751

Response time

depending on configuration

Max. process pressure (static)

depending on the configuration up to 500 bar

Operating temperature range

PT100 TF iTHERM StrongSens:

Max. immersion length on request

84"

Accuracy

class A acc. to IEC 60751

Response time

t50 = 1 s

Max. process pressure (static)

at 20 °C: 50 bar (725 psi)

Operating temperature range

PT 100:

Max. immersion length on request

up to 600,00 mm (23,62'')

Response time

t50 = 2.5 s

Max. process pressure (static)

at 20 °C: 40 bar (580 psi)

Operating temperature range

Pt100:

Max. immersion length on request

up to 900.00 mm (35.4'')

Response time

t50 = 2,5 s

Max. process pressure (static)

at 20 °C: 40 bar (580 psi)

Operating temperature range

PT 100:

Max. immersion length on request

up to 28'' (711 mm)

Do you need help selecting and sizing your next device?

Comfortably select, size and configure best-fit products for your measuring tasks and application.

Instrumentation for temperature measurement

Endress+Hauser offers a complete assortment of temperature sensors, thermometers and their components such as thermowells with a huge variety of process connections and neck/lagging versions, terminal heads, transmitters, measurement inserts and further accessories for all types of process industries.

Thermometers & temperature transmitters

Our expansive portfolio offers globally available, standardized thermometers to measure temperature in industrial and hygienic applications across all process industries. We enhance plant availability, efficiency and safety through outstanding customer-centric innovations. Our internationally tested and certified products ensure seamless integration, ease of use and long-term reliable performance.

In combination with Endress+Hauser transmitters, our temperature assemblies are the perfect fit for all industries and a wide range of applications. Different housing types, various digital and analog output signals, approvals and more ensure an optimal selection and make the thermometers suitable for a wide range of control systems.

Plant safety and trouble-free plant certification: International approvals for metrology, hazardous areas, safety and moreSeamless system integration: All common protocols - from analog to digital outputsLow operating costs: Easy handling from installation to maintenance, long lifetimeEnhanced efficiency and safety: Outstanding measurement performance, broad certification, customer-centric innovationsHigh plant productivity and availability: Reliable, accurate sensor technology and traceable, accredited calibrationsWorldwide availability: From instrumentation to support, services and solutions

Learn more about temperature sensors and the measuring principles

What is a thermometer and what is special about thermometers used in process automation?

A thermometer is an instrument that measures temperature. Temperature measurement is a fundamental aspect of science and daily life, from cooking to weather forecasts. It is the most frequently measured parameter in the process industry and highly relevant for process safety, efficiency and the quality of the final products.

Temperature sensors and their measurement data are the decisive factor in a large number of industrial processes, therefore the devices need to be reliable and accurate. Standard instruments to measure temperature in our everyday life are not comparable to industrial temperature sensors for several reasons.

Infrared thermometers measure temperature from a distance by detecting infrared radiation emitted by objects. Factors such as material and surface properties influence the emissivity and therefore the accuracy of this measurement. This may cause inaccuracies in harsh and changing conditions. Moreover, in industrial processes, the variable to be measured is typically the temperature of the medium in a pipe or container and not the surface temperature, which is detected by the infrared measurement.Household thermometers often contain a liquid in a narrow glass tube that expands when heated and hereby indicates temperature changes. Mercury is one of the most familiar materials used in liquid thermometers. The fragile materials and high contamination risk make them unsuitable for harsh and often high-pressure industrial environments.Electronic thermometers with digital displays are widely used in portable devices or for measuring room temperature. They can monitor body temperature and ambient temperature, providing data for health monitoring and environmental awareness. They are cost-effective and compact but do not fulfill the requirements for industrial use in terms of accuracy, robustness and long-term stability.For these reasons RTD (Resistance Temperature Detector ) or thermocouple sensors are preferred in industrial processes. These are designed to precisely and reliably measure temperature within pipes or tanks in harsh process conditions.

What are the different units for temperature measurement?

The three most common units for temperature monitoring are Celsius, Fahrenheit, and Kelvin. The Celsius scale is part of the metric system, while Fahrenheit is part of the imperial system. To convert Celsius to Fahrenheit, multiply the Celsius temperature by 1.8 and then add 32. For example: The boiling point of water is 100 degrees Celsius and 212 degrees Fahrenheit. The Kelvin scale does not use degrees; it uses the kelvin (K) as a unit of measurement. The Celsius and Fahrenheit scale are most used for temperature measurement, while the Kelvin scale is often used in scientific research or indication of temperature differences.

Which types of process instrumentation to measure temperature exist?

Invasive (direct contact)

In pipes or containers, the fastest and most accurate measurement can usually be achieved with a direct immersion thermometer without a protective tube (thermowell). However, this is not feasible in many applications and has various disadvantages. For example, to remove or replace the thermometer, the process must be shut down and the pipe may need to be drained. In addition, direct installation carries the risk of contamination and rapid wear, especially if the thermometer is exposed to harsh process conditions such as corrosive or abrasive media.

Invasive (with thermowell)

An invasive measurement with a thermowell offers the possibility of exchanging the temperature sensor without interrupting the process. In addition, if the protective tube material and geometry are selected to suit the process, the thermometer can have a very long service life. However, thermowells disrupt the process flow, lead to a pressure loss in the pipeline and are also subject to wear, which can require regular maintenance and, if necessary, the replacement of protective tubes, especially in critical applications. The use of protective tubes typically reduces the response time of a thermometer compared to direct contact thermometers.

Non-invasive (surface measurement)

New thermometric techniques have been developed that allow monitoring of process temperature without inserting a sensor into the process medium. These non-invasive temperature sensors are mounted on the surface of the pipe or vessel. Intelligent design and advanced technologies ensure optimum heat flow to the sensor element, which minimizes the measurement error and uncertainty. Since these temperature sensors do not penetrate the pipe wall, typical problems as leakage, wear or negative effects on the process can be avoided. Non-invasive thermometers are easy to install, can be retrofitted and are almost maintenance-free. However, external factors such as the ambient temperature and surface conditions can the impact measurement accuracy. For this reason, thermal insulation of the measuring point is recommended for most applications.

What are the components of a temperature assembly?

The insert is located in the thermowell , with the thermowell being the process wetted component of the assembly. It increases the lifetime of the measurement insert by protecting it against harsh process conditions (corrosion, abrasion, process pressure etc.) and allows to exchange the measurement insert without process interruption.

The tip of the measurement insert contains the temperature sensor element , the most important component, as it provides precise and reliable measurement data through an electrical signal.

In order to transmit the raw signal towards the process control system, it is necessary to convert it into a standardized analog or digital signal. This conversion is the task of the transmitter - it acts as a smart interface between the sensor and the PLC. It offers enhanced accuracy and signal stability, reduced wiring costs and advanced diagnostic functions.

The transmitter is placed in the terminal head, which is fitted to the thermowell or the neck of the thermometer. It protects the transmitter and acts as a junction box for wiring all different components. Some terminal heads also provide a local display for indication of measurement values and status information.

Other components are the process connection , the connection between the process and the thermometer, and the extension neck , the connection between the terminal head and process connection/thermowell. The neck protects the head transmitter from overheating by creating a distance to the often hot process temperatures. It also guarantees access to the terminal head in the case of pipe insulation.

What are the most common types of temperature sensors used in industrial applications? What’s the difference between thermocouples and resistance temperature detectors?

Both RTD and TC are widely used in industrial applications to measure temperature. Choosing between thermocouple and resistance temperature detector depends on the specific requirements of the application including temperature range, accuracy, environmental conditions, and budget.

RTDs excel in accuracy, linear response, long-term stability, and resistance to electrical noise, making them ideal for precisely and reliably measuring temperature in controlled environments.

Thermocouples are advantageous for their wide temperature range, durability, fast response time, and cost-effectiveness, making them suitable for extreme industrial conditions and high-temperature applications.

Most methods for monitoring temperature rely on physical properties of materials that vary with temperature. Temperature can be measured by examining changes in physical properties e.g. electrical resistance or voltage. Industrial temperature sensors typically use two types of measurement principles:

1. Resistance Temperature Detector (RTD)

Negative Temperature Coefficient (NTC): These sensors exhibit higher resistance at low temperatures and lower resistance at higher temperatures. / Positive Temperature Coefficient (PTC): These sensors exhibit lower resistance at low temperatures and higher resistance at higher temperatures.

In industrial processes, resistance temperature sensors are most common. An RTD is typically made of high-purity metals. The temperature sensor typically consists of a length of wire made from pure metals such as platinum, nickel, or copper. The electrical resistance of the sensor metal increases as the temperature rises. This change in resistance is measured and converted into temperature readings. Resistance thermometers in industrial processes typically use a platinum sensor, either a Pt100 or Pt1000 temperature sensor. These sensors are standardized e.g. according to IEC 60751. The Pt100 temperature sensor is a temperature-sensitive platinum resistor with a resistance of 100 Ω at 0 °C (32 °F) and a temperature coefficient α = 0.003851 °C-1

2. Thermocouples (TC)

Thermocouples are comparatively simple, robust temperature sensors which use the Seebeck effect for temperature measurement. If two electrical conductors made of different materials are connected at a point, a weak electrical voltage can be measured between the two open conductor ends if the conductors are subjected to a thermal gradient. This voltage is called thermoelectric voltage or electromotive force (emf). Its magnitude depends on the type of conducting materials and the temperature difference between the "measuring point" (the junction of the two conductors) and the "cold junction" (the open conductor ends). Accordingly, thermocouples primarily only measure differences in temperature. The absolute temperature at the measuring point can be determined from these if the associated temperature at the cold junction is known or is measured separately and compensated for. The material combinations and associated thermoelectric voltage/temperature characteristics of the most common types of thermocouple are standardized in the IEC 60584 and ASTM E230/ANSI MC96.1 standards.

What are the different types of resistance temperature detectors?

Thin-film platinum resistance thermometers (TF): A very thin, ultrapure platinum layer, approx. 1 μm thick, is vaporized in a vacuum on a ceramic substrate and then structured photolithographically. The platinum conductor paths formed in this way create the measuring resistance. Additional covering and passivation layers are applied and reliably protect the thin platinum layer from contamination and oxidation, even at high temperatures. The primary advantages of thin-film temperature sensors over wire-wound versions are their smaller sizes and better vibration resistance. A relatively low principle-based deviation of the resistance/temperature characteristic from the standard characteristic of IEC 60751 can frequently be observed among TF sensors at high temperatures. As a result, the tight limit values of tolerance class A as per IEC 60751 can only be observed with TF sensors at temperatures up to approx. 300 °C (572 °F).Wire-wound (WW): In these thermometers, a double coil of fine, high-purity platinum wire is accommodated in a ceramic support. This support is then sealed top and bottom with a ceramic protective layer. Such resistance thermometers not only facilitate very repeatable measurements but also offer good long-term stability of the resistance/temperature characteristic within temperature ranges up to 600 °C (1112 °F). This type of sensor is relatively large in size and comparatively sensitive to vibrations.

Why should I use a temperature transmitter instead of direct wiring?

Using a transmitter offers several advantages over direct wiring. While direct wiring simply transmits the raw sensor signal, a transmitter enables communication through various analog and digital protocols such as Profinet (via Ethernet-APL) or IO-Link. This allows seamless integration into the plant’s digital communication infrastructure. Bluetooth-enabled transmitters even allow for particularly easy configuration and remote control.

Transmitters provide more than just the measured value. They can deliver additional diagnostic and status information, enhancing process reliability. Furthermore, transmitters can "smartify" the thermometer or measurement point, turning them into intelligent nodes within the system. This not only improves data quality and accessibility but also supports predictive maintenance and efficient process control.

Which factors can affect the accuracy of temperature measurements in industrial environments? How can the accuracy of an industrial thermometer be increased?

The accuracy of temperature sensors depends on several factors:

Sensor accuracy: temperature sensors have standardized accuracy classes according e.g. IEC60751 or IEC60584. Platinum RTDs (resistance temperature detector) typically offer more accurate temperature measurement compared to TCs (thermocouples). Temperature transmitter accuracy: the performance characteristics of the transmitter have a direct influence on the overall accuracy of the thermometer. Installation conditions and thermometer design: correct and smart design of the measurement point and temperature sensor has the biggest influence on overall measurement performance and accuracy. Properties like immersion length, thermal masses, thermal conduction and coupling, thermal insulation from ambient conditions, material properties and more are to be considered and wisely orchestrated. Suitable design and technology is vital for achieving best possible measurement performance. If not done correctly, even the most sophisticated sensor or transmitter technology cannot achieve good results. Often too little attention is paid to installation conditions and thermometer design. Endress+Hauser can help you to design your measurement point optimally.

Sensor-transmitter-matching by Endress+Hauser offers additional reduction of the thermometer measurement uncertainty. It ensures the highest accuracy when ordering a thermometer including a transmitter. With an in-house calibration, the individual sensor characteristic curve is determined and stored in the transmitter via the Callendar-Van Dusen coefficients . In this way, sensor and transmitter are optimally tuned and measurement deviations are reduced to a minimum.

What is a calibration and how often should industrial temperature sensors be calibrated?

A calibration is the process of verifying the accuracy of the measurement device (thermometer) by comparing its readings to a known standard or reference. This ensures that the device accurately and reliably measures temperature within defined tolerances.

Temperature is a crucial parameter for many processes determining product and plant safety as well as process efficiency. To ensure long-term stability and safety, regular calibration (recalibration) is necessary. The frequency of recalibration intervalls should be determined depending on the temperature sensor type, the process conditons, the criticality of the temperature measurement point and imposed risks arising from deviations. The frequency of recalibration is usually determined by balancing effort and risk based on experience and knowledge.

A clever and unique option is the Endress+Hauser self-calibrating compact thermometer iTHERM TrustSens. It reduces risks and costs by a fully automated, traceable inline self-calibration. The hygienic thermometer makes use of the Curie effect, having a built-in, long-term stable fix point reference with complete traceability of the calibration chain according to ITS-90.

How do I choose the right temperature sensor for my industrial process?

Consider your application and process data to make the right choice. Most important factors are process temperature range , required measurement performance such as accuracy & response time , installation and environmental conditions . The selection and configuraton of each thermometer (e.g. invasive vs. non-invasive, direct contact vs. thermowell, resistance temperature detector vs. thermocouple, transmitter model and communication protocol, necessary approvals such as hazardous areas or SIL requirements, type of process connection and all other components) depends on these factors.

Endress+Hauser offers a complete and highly flexible range of thermometers for measuring temperature, as well as components that ensure the best possible measurement solution for any industrial application in process automation.

Industrial thermometers: Hygienic thermometers: Compact thermometers Multipoint thermometers High temperature sensors include innovative thermowell materials such as non-porous ceramics with improved wear and chemical resistance. The thermocouple sensors can measure temperature in applications up to +1700 °C (+3092 °F) in furnaces or melts e.g. in the metal industry, waste incinerators, cement production or glass industry. Surface or non-invasive temperature sensors are used to measure the process or pipe temperature by only touching the outer surface of the pipe (or vessel). They reduce the risk of leakage and prevent flow problems in small pipes, in pipes that require pigging, and in highly corrosive or abrasive applications. Cable probe temperature sensors Using the Endress+Hauser product configurator helps you create a thermometer to measure temperature in your process, deciding on the version of every single component. All components to measure temperature such as thermowell, transmitter, terminal head, process connection, neck/lagging, measurement insert, temperature sensors and further accessories are available from Endress+Hauser.

Show more

Show less

Redefining non-invasive temperature measurement!

iTHERM SurfaceLine TM611 measures process temperature without the risk of leakage and process disruption while offering superior measurement performance compared to electronic compensation.

Tải xuống

Khám phá thêm tài nguyên

Đo nhiệt độ trong quy trình công nghiệp

Đo nhiệt độ - Nhiệt kế và bộ hiển thị cho quy trình công nghiệp

Tải xuống

Chúng tôi tôn trọng quyền riêng tư của bạn

Chúng tôi sử dụng cookie để nâng cao trải nghiệm duyệt web của bạn, thu thập số liệu thống kê để tối ưu hóa chức năng của trang web và cung cấp nội dung hoặc quảng cáo phù hợp.

Bằng cách chọn "Chấp nhận tất cả", bạn đồng ý với việc sử dụng cookie của chúng tôi. Chính sách cookie của chúng tôi.

Tùy chỉnh

Chấp nhận chỉ cần thiết

Chấp nhận tất cả