MRO is frequently seen as a challenge and high-cost. However, it is necessary to ensure the availability of parts that support equipment reliability. Among the challenges are integrating end-to-end planning, increasing reliability and availability of physical assets, optimizing inventory and realizing effective spend management. With our approach we support you in MRO optimization of your chemical plant.

Dữ kiện chính

65%

of the annual net profit is equal to the maintenance budget of a production facility today

According to experts, maintenance is last on the list of significant controlled expenditures

Improve the availability of your chemical process

Following the steps of our proven process workshop you can improve your MRO workflow and save time and money through maintenance optimisation.

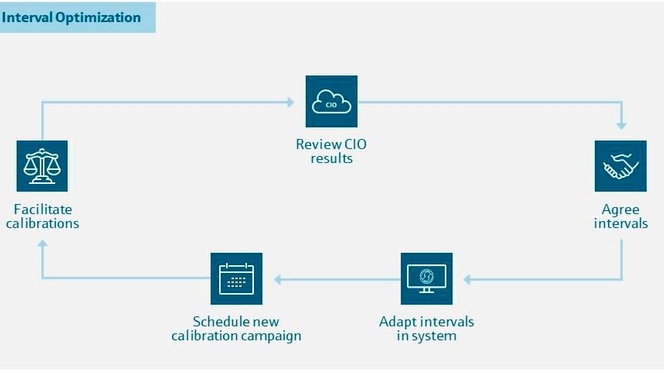

After calibration, interval calculations are triggered and the next optimal calibration interval is calculated. This procedure ensures a calibration program in which drifts are detected early.

Following the steps of our proven process workshop you can improve your MRO workflow and save time and money through maintenance optimisation.

After calibration, interval calculations are triggered and the next optimal calibration interval is calculated. This procedure ensures a calibration program in which drifts are detected early.

Business Process Consultancy

Efficient process optimization or successful project implementations do not only happen on paper, it also happens in people's minds and the way they work. Therefore, we have developed a standard service fit for the general process industry, based on generic Business Process Management models. Our offering for MRO optimization in your chemical plant helps you to make the right decisionsoptimise maintenance and ensure safety.

Our expertise in the field

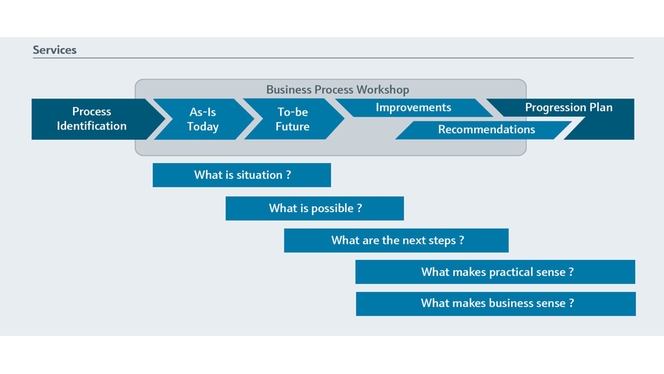

In a business process workshop we support you in defining the content of all relevant steps. The "As-Is" analysis represents the actual situation. This step is needed to understand the change in impact from the current situation to a new one. The “To-Be” situation includes the process description, new system architectures, associated work flows and the information exchange between the different systems in chemical plants. It represents a realistic and best possible solution.

- The outcome helps everyone understand what the needed "pain relievers" are and what is achievable by implementing necessary actions.

- A comprehensive document presents the pay-back scenarios and/or potential savings. These results will be presented to your stakeholders and management to ensure their buy inn.

- The methodology is applied more than 70 times in several industries including the chemical industry. Due to the structured approach and the clear phased progression plan of improvement recommendations, the success is more sustainable.

Calibration Interval Optimization

Today most chemical manufacturers base their calibration intervals on arbitrarily fixed dates. While that may fulfill legal obligations it also results in instruments being calibrated too often or not often enough, leading to either wasted resources or increased risk. Traditionally, calibration is often scheduled for the annual shutdown. While this may be convenient, leading bodies such as the ILAC do not recommend fixed calibration intervals without review, as they are not considered reliable.

Our expertise in the field

Our service product Calibration Interval Optimization (CIO) uses a scientifically proven method to calculate the next optimal calibration date. This method factors in drift, risk and other issues to optimize your calibration intervals to your process needs It helps you to gain operational efficiency and to achieve your maintenance budget targets. At the same time it minimizes the risk because every instruments gets the exact amount of calibration that it needs. CIO allows you to:

- optimization of chemical plant maintenance by extending calibration intervals and cost reduction (as far as possible)

- reduce risk (where necessary) by reducing calibration intervals and ensures safety

Benefits

Your success is our main objective. No matter how challenging your maintenance objectives are, our experts will support you in optimization. We will support you through implementation of a sustainable obsolescence program, helping meet availability and reliability goals of your chemical process.

Dữ kiện chính

67%

of current calibration intervals can be significantly increase

Dữ kiện chính

50%

of your stock reduced by using a sustainable obsolescence program

Dữ kiện chính

25%

of your uptime increased by implementing the perfect balanced MRO optimization strategy based on a proven methodology

How we can help

We help to optimize your MRO processes by providing an an efficient, effective and paperless asset management solution that integrates with your business processes and reduces cost and error. Our MRO experts identify potential application areas in chemical plants where we can increase safety, gain efficiency or reduce maintenance costs. Following proven methods we help you optimize your work flows through:

- business process consultants that conduct a workshop: by going through the existing situation (As-Is) the improvement potentials are discovered. These improvements and new solutions are used to design an improved situation (To-Be).

- optimized calibration activities: our Calibration Interval Optimization service provides sustained calibration intervals based on scientific methods that rely on data rather than tradition.